SKIDABRADER

TECHNOLOGY

Wet weather accidents have been dramatically reduced or, in some cases, eliminated by modifying asphalt and concrete pavement surfaces with the Skidabrader™, which uses our unique technology of high-velocity bidirectional abrading and retexturizing. This system was designed for the safety and beautification of structurally sound highways, runways, bridges, and other large traffic-bearing surfaces.

SKIDABRADER UNIQUE PATENTED PROCESS

Skidabrading incorporates using a high-speed wheel to propel steel shot in a controlled pattern towards a substrate. The steel shot's high-speed impact abrades and removes contaminants while etching the surface. The steel shot rebounds into an air wash separator, where it is cleaned and returned to the blast wheel for reuse. The contaminants are collected within a containment system for later disposal.

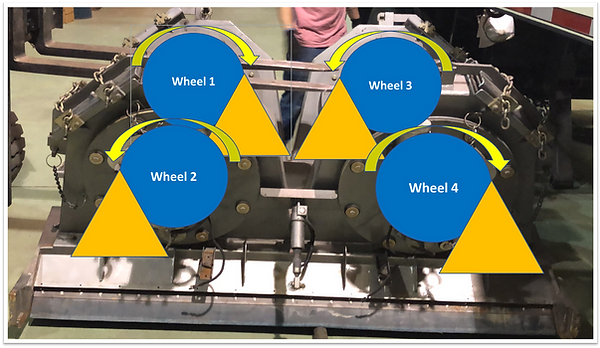

CLOSE UP OF WORKING ROTATION

SKIDABRADER™ PATENTED WHEEL DESIGN

Our Skidabrader wheel design allows for infinite control and feathering of the blast pattern. These unique controls allow for velocity and abrasive flow changes to achieve variable surface outcomes.

Macrotexture is relatively stable and can be measured by traveling at normal speeds using laser profile meters. This is recorded as SMTD [Sensor Measured Texture Depth].

Microtexture

the texture of the stone

Macrotexture

overall the texture of the road

MACRO AND MICRO TEXTURING

Aggregate Characteristics

Surface Characteristics

Microtexture

Macrotexture

Megatexture

Roughness/Unevenness

X

X

X

FRICTION

EXTERNAL NOISE

INTERNAL NOISE

SPRAY/SPLASH

ROLLING RESISTANCE

TIRE WEAR

TIRE WEAR/DAMAGE

The abrasion process targets and alters the desired pavement's macrotexture. Macrotexture is the primary pavement characteristic associated with the Microtexture. It is effectively the average depth of the gaps or voids between the coarse aggregate particles on the surface.